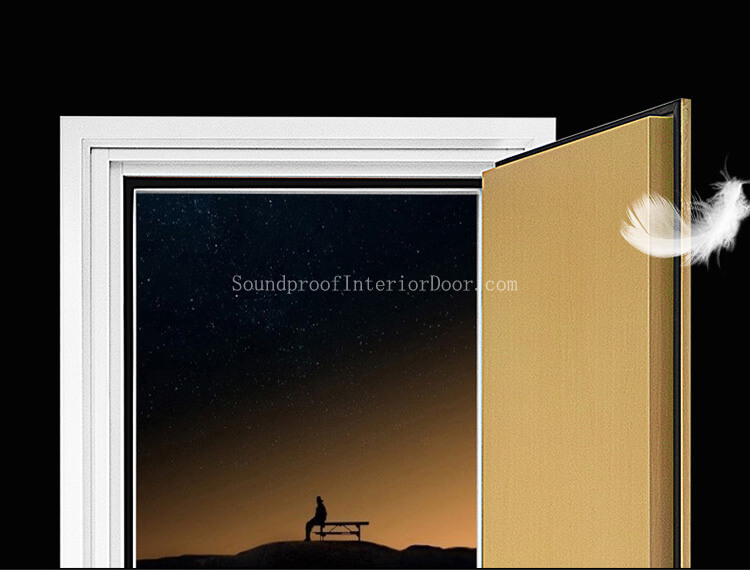

Soundproof Interior Door Manufacturer

Soundproofing Studio Doors

Noise not only reduces attention, but also causes stress and causes permanent illness. This is why it is important to isolate noise at its origin. Our soundproofing doors for studio makes a significant contribution with acoustic values up to 45 dB.

Soundproofing Studio Doors Highlights:

Available in galvanized, low carbon steel and stainless steel.

The tag gate for STC (sound reduction) is 45 dB.

High aesthetic and robust structure.

Built-in fire rating.

Standard size of soundproofing studio doors: (H) 2100mm * (W) 1000mm (height * width).

Custom size: door width: single leaf < 1000mm, double leaf < 2000mm; door height < 3000mm.

Clear Vision lite is available upon request for soundproofing door for studio.

The acoustic door material factory was completed for Primer and Paint Finish.

The factory is ready to receive all types of hardware.

Acoustic Rating of Studio Soundproofing Doors:

Combine professional manufacturing methods with rigorous processing procedures. The sound transmission level of the laboratory test is 45 dB.

Sound insulation design class:

The door has a single steel door of 40-45dB.

Double door steel door with a threshold of 35-40dB.

Soundproofing Studio Doors

Door structure: thickness 60-75mm, made of galvanized steel door, full paint coating, full of sound absorbing and damping components.

Frame: The Z-section frame is fixed.

Assembly: All components will be assembled and adjusted at the factory to ensure easy installation, reliable operation and acoustic performance prior to shipping and installation.

Hinge: The surface mount belt hinge made by the manufacturer matches the soundproof industrial steel doors.

Acoustic seal: The side and head of the door frame should receive two sets of acoustic seals according to the specifications/requirements of the acoustic engineer. An automatic door bottom seal will be installed at the bottom of the soundproofing studio door and will press against the floor when the door is closed.

Soundproofing Studio Door Installation Technical Description:

Each soundproof studio door is assembled at the factory. The independent door frame structure not only adapts to different wall thicknesses, but also is convenient and quick to install. It is checked by verticality, fit and easy operation before leaving the factory.After the customer have got the acoustic door materials, the door frame needs to be filled with cotton, polyurethane foam + filled structural glue or cement mortar.